Portable runway lighting application

As LEDs become cheaper and significantly more efficient than traditional light sources, many companies are looking at updating their lights to take advantage of the benefits that LEDs offer.

As LEDs become cheaper and significantly more efficient than traditional light sources, many companies are looking at updating their lights to take advantage of the benefits that LEDs offer.

AGI manufacture portable runway lights that are used in harsh environments and battery operated. As a result they have the following requirements for their lighting systems:

- Compact design

- High efficiency

- Easy to manufacture

- Meet regulatory requirements (as defined by the FAA in the US and the ICAO in Europe)

Amongst the lights that have been updated to meet the requirements are the Precision Approach Path Indicators (PAPI).

PAPI Specification

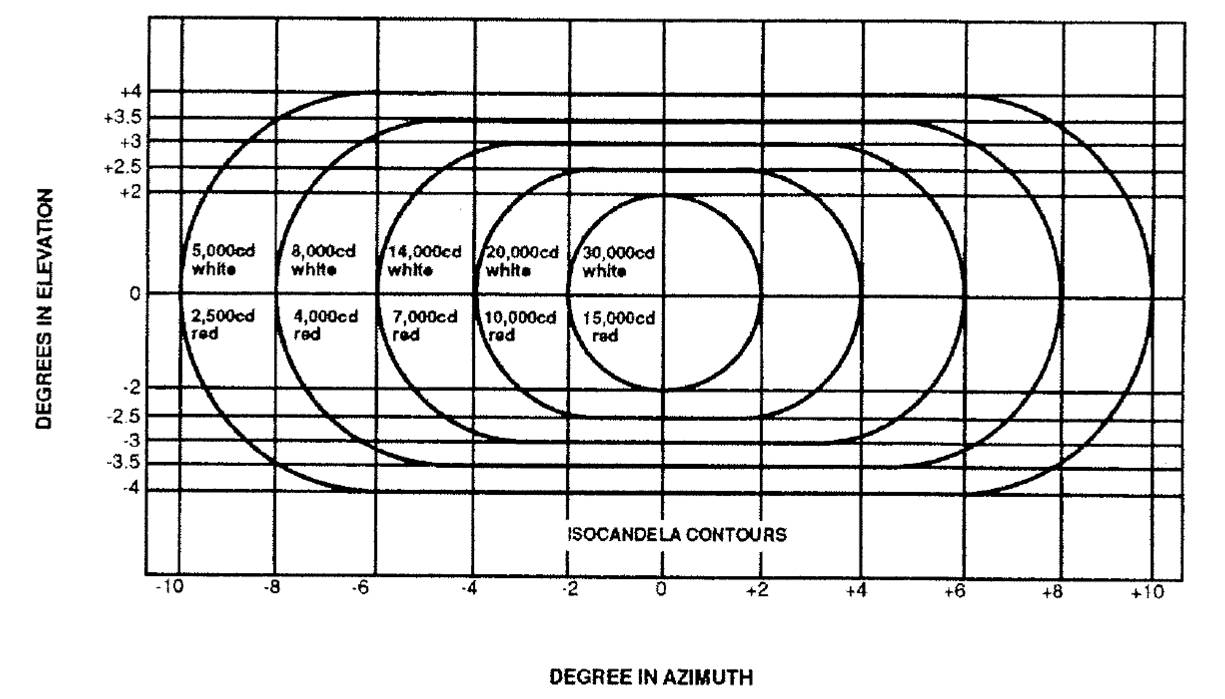

The detailed specifications for the performance of the PAPI include:

- 2 sectors (1 red and 1 white light) each spanning an angular range of 4×20o

- Rapid colour transition between the sectors over 3 arcminutes

- Light intensity profile within the sectors as shown in the figure below.

Optical system design

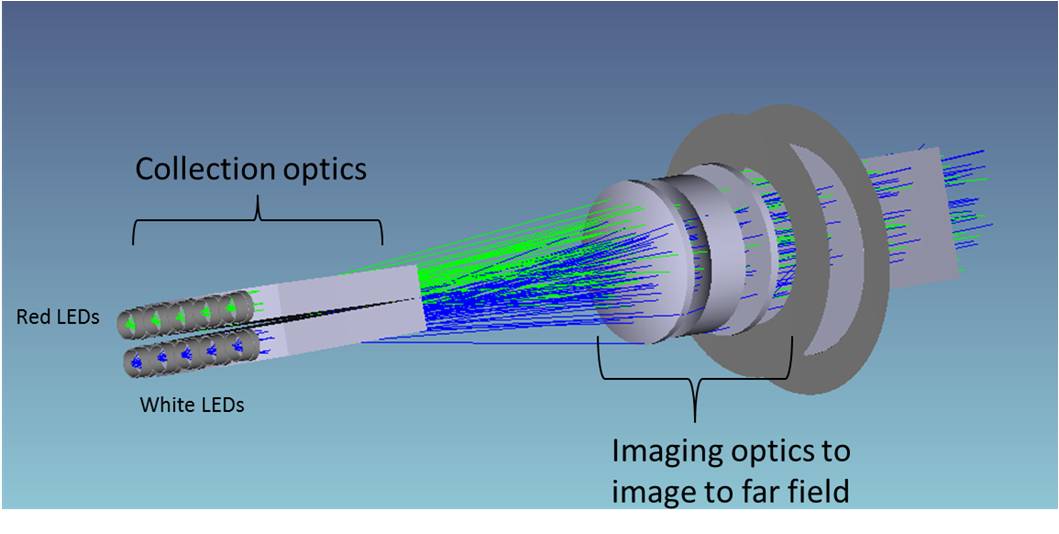

The design of the optical system was separated into 2 parts. In the first section, the light from the LEDs is collected and coupled into a waveguide to create the required illumination pattern at the output of the waveguide. A projection lens is then used to image the output of the waveguides into the far field. The field of view of the projection lens on the input side matches the angle into which the light from the LEDs is collected. The main approach is illustrated in the diagram below.

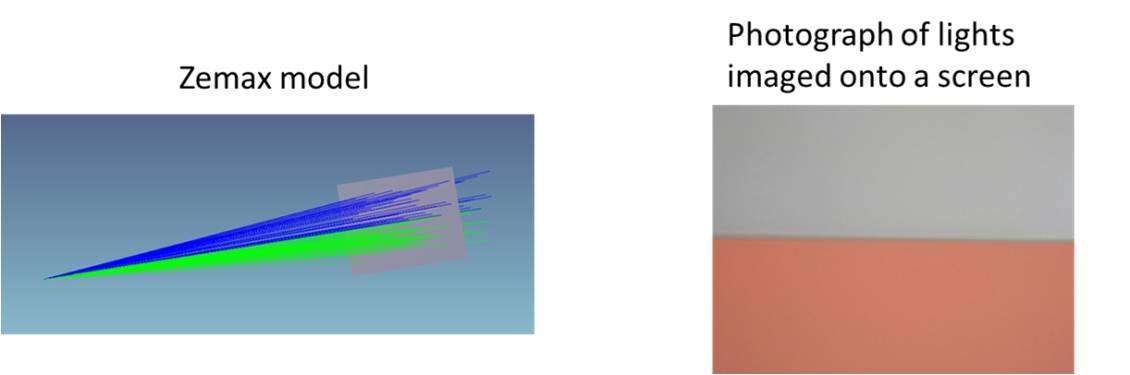

In the far field the colours have separated out as required:

The final design has a number of features which enabled the system to meet the specifications and be manufacturable and come in at a cost within the budget for the system:

- Use of off the shelf lenses to collect the light from the LEDs

- The use of the waveguide had a number of benefits:

- Smoothes out the illumination pattern to meet the requirements in the specification

- Keeps the light from each colour separate until the waveguides meet at the image plane of the projection lens

- The LEDs can be attached to a single PCB with a common back plane to simplify the handling of the electronics

- Enables a single projection lens to be used

- Simplifies assembly of the final unit

- Although the projection lens is a large expensive item, it replaced two separate lenses in the original system and so the overall cost was reduced. In addition, the use of waveguides and a single lens means that the 2 sectors do not need to be separately aligned, simplifying the manufacture of the approach lights.

The product has now been successfully transferred into production and is being deployed around the world including in Antarctica.